| Hours today: |

2.7 |

Hours wings: |

178.5 |

Hours total: |

272.8 |

| Rivets today: |

0 |

Rivets wings: |

3558 |

Rivets total: |

5637 |

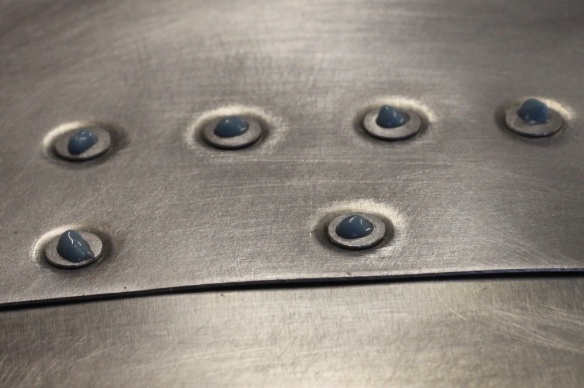

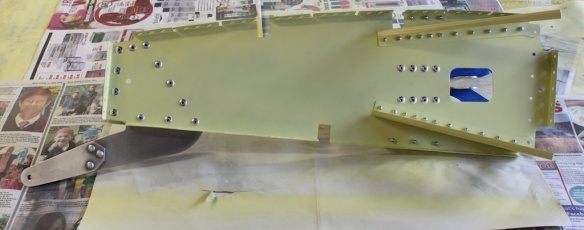

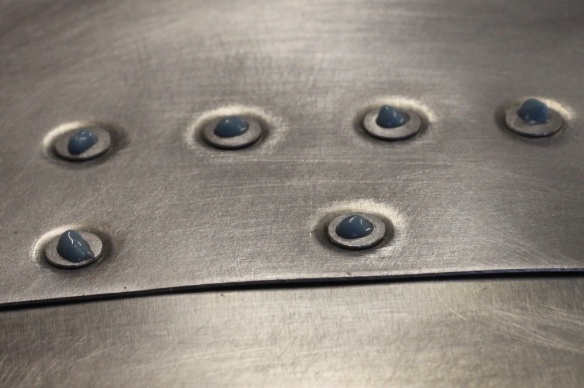

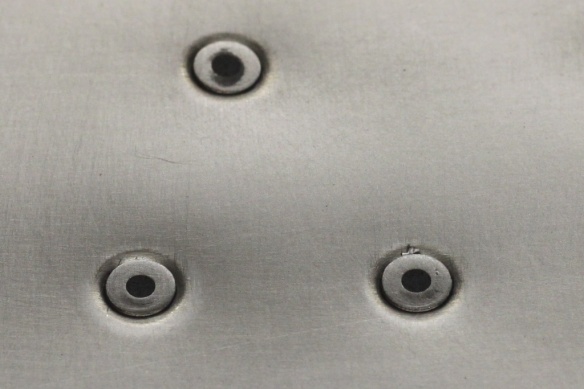

Worked out a recipe for filling rivets. It might well get adapted later. First, inject filler into the hole in the rivet, leaving a slight molehill:

Rivet centres filled.

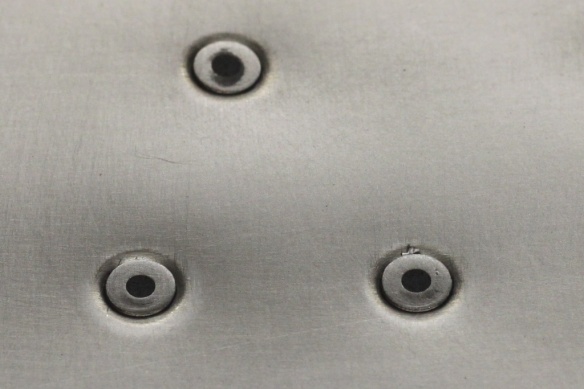

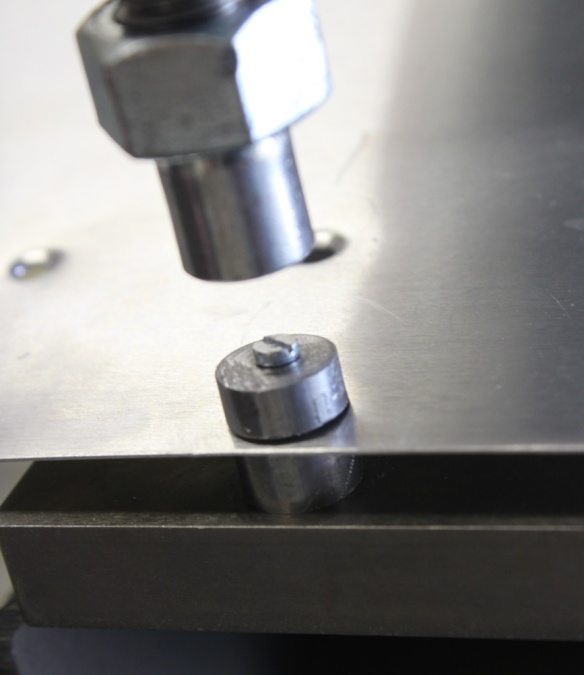

Wait for the molehills to dry, then cut them off flat:

Rivet molehills flattened.

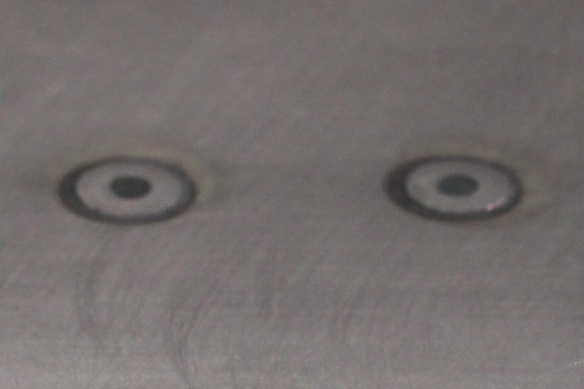

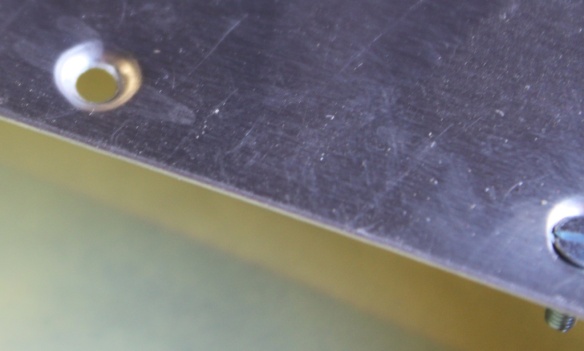

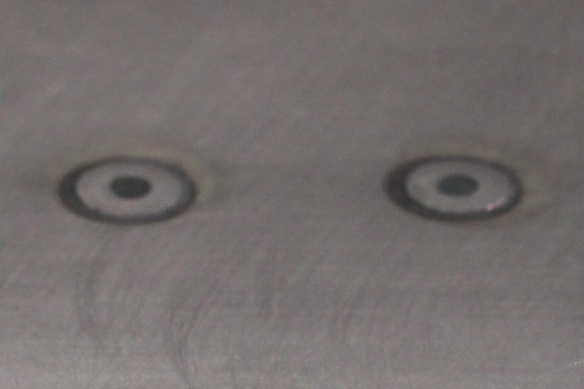

Then put a ring or blob of filler over the whole area, and wipe off excess with a paper towel dipped in lacquer thinners (apologies for the poor photo below). I started by just removing the bulk of the filler with a wooden tongue depressor, used as a knife, then let the filler dry. I only removed the excess once things were dry, using lots of thinners and elbow grease. Later on, I switched to removing the filler while it was still wet, which is much easier.

Rivet with donut of filler around it.

The centre needs to be injected, because otherwise the hole only gets a thin layer which easily pops. I’m not certain if the donut is required or if the paint will cover it, but I think it’s going to give me the effect I want: obvious rivet postions, but not obviously pop rivets.