| Hours today: | 1.4 | Hours wings: | 210.6 | Hours total: | 309.5 |

| Rivets today: | 0 | Rivets wings: | 3786 | Rivets total: | 5865 |

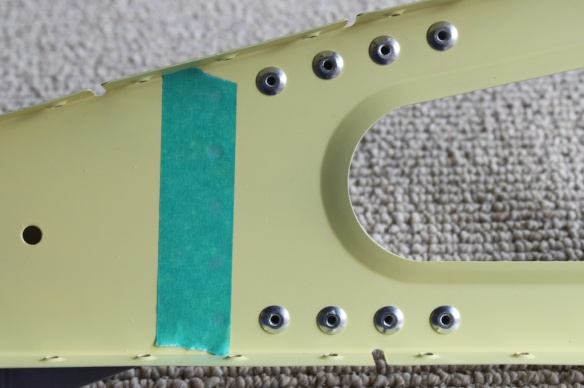

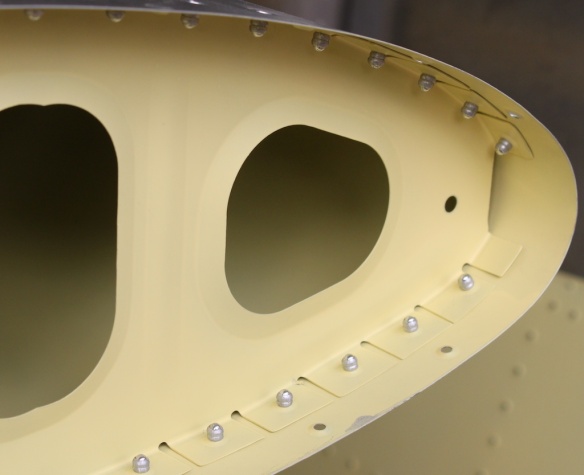

I worked out that the best way to position the lower edge of the wingtip relative to the skin was to mark a line on the wingtip that should go in line with the edge of the skin. In the poor photo below, the original position of the holes is marked by the horizontal stroke, which would have been too close to the edge. The second attempt was the crosses, but I didn’t have faith in them, so I drew the line, then drilled a couple of holes while holding the line in the desired position.

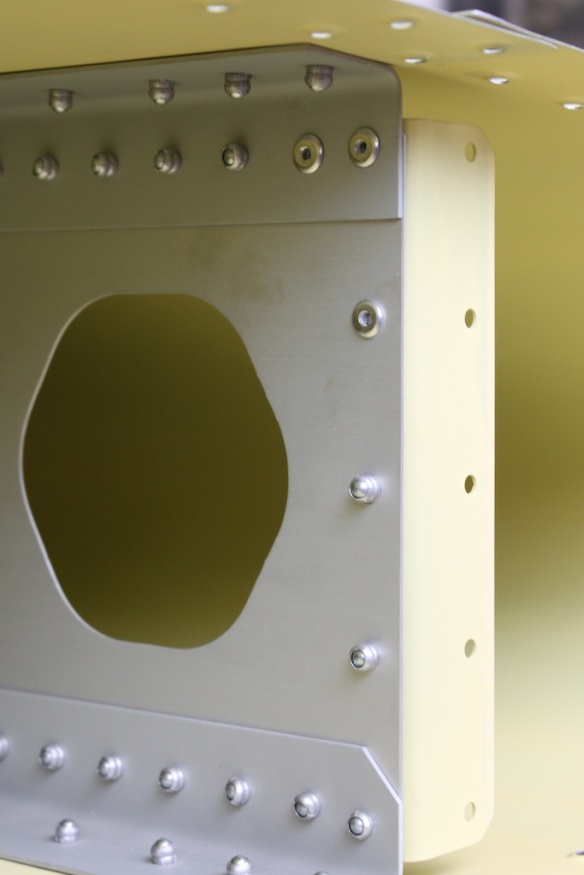

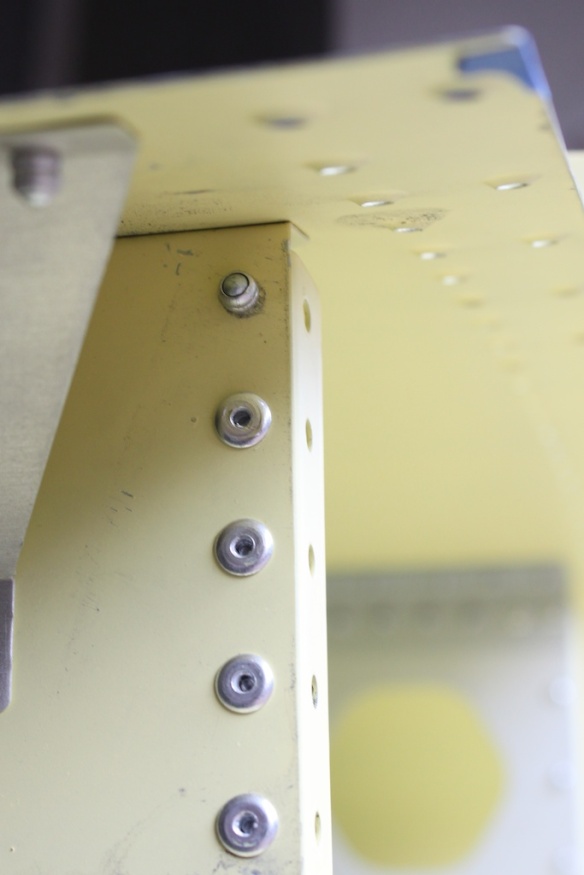

After getting a couple of holes in the right places, I cleco’d the wingtip in place and started to drill the other holes. I very quickly found that on the bottom, the drill was getting through the composite, then pushing the aluminium strip away rather than drilling through it. Instead, I marked the desired drill positions with shallow drill holes, then took the wingtip off and drilled with a wooden block against the back of the hole to keep the alumium strip in place.

It didn’t work well enough, the lower strip just wasn’t well enough glued. I had used Pratley’s transparent pro expoxy, which comes in a joined pair of syringes. Something to do with the bottom layer just wasn’t good enough though.

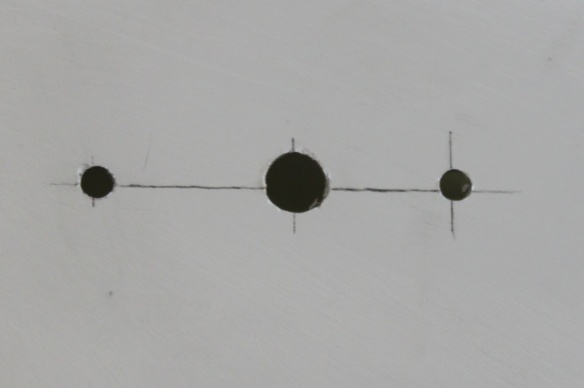

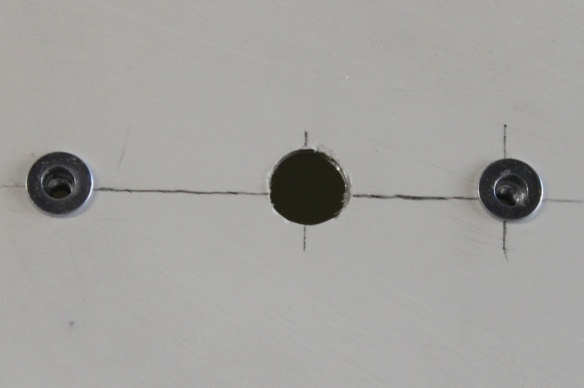

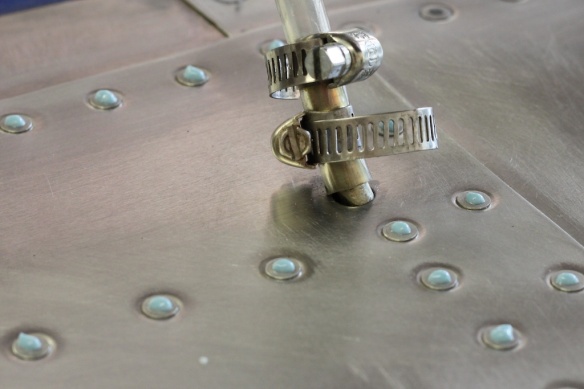

Before fixing the problem, I countersunk all the holes, first in the countersink tool, which gave the aluminium the right shape, then by drilling countersunk holes.

Final countersunk holes in the wingtip skin. The aliminium layer is just visible at the bottom of the left hole.

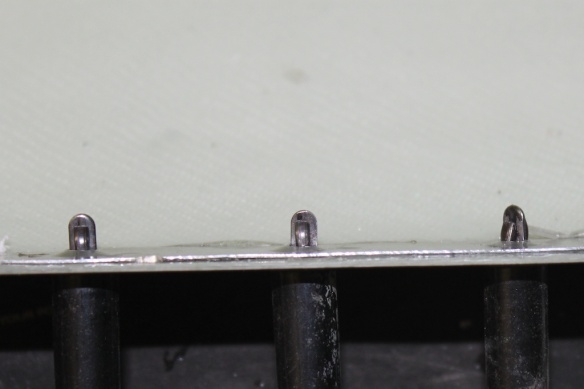

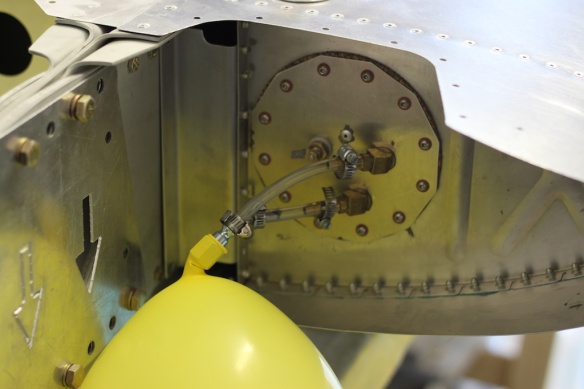

Finally, I took the lower aluminium strip off properly, cleaned it and the wing and glued in back using Pratley’s Ezee Bond, advertised as specifically for metal and fibreglass. Once the two parts are mixed it has the consistency of honey mixed with chewing gum. It is also advertised as not needing degreasing, and seeing how tenacious it was, I can believe that. To hold the strip in place, I used clecos in all the holes.

I don’t even need the aluminium to stay stuck for very long – just long enough to put the rivets in. Let’s hope this solution works.