18 August

| Hours today: | 2.2 | Hours fuse: | 196.3 | Hours total: | 613.1 |

| Rivets today: | 0 | Rivets fuse: | 3879 | Rivets total: | 12 182 |

Not much in the way of photos, because the work is not very photogenic. Smoothed all the rivet heads on the rear fuselage.

19 August

| Hours today: | 1.8 | Hours fuse: | 198.1 | Hours total: | 614.9 |

| Rivets today: | 0 | Rivets fuse: | 3879 | Rivets total: | 12 182 |

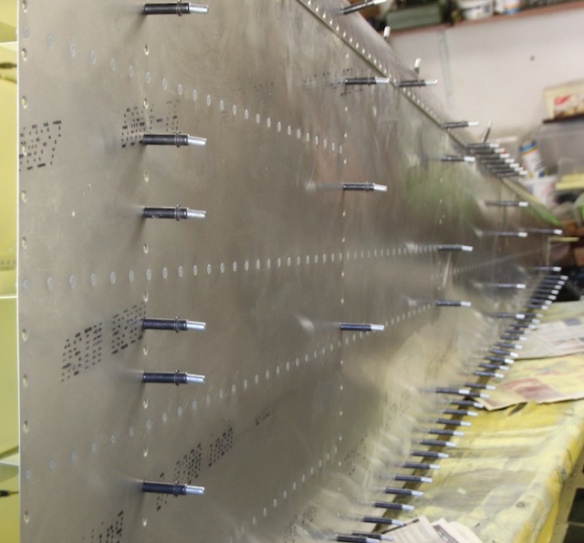

Filled rivets on the rear fuselage. Did some test fitting of the rudder cables.

20 August

| Hours today: | 4.3 | Hours fuse: | 202.4 | Hours total: | 619.2 |

| Rivets today: | 1 | Rivets fuse: | 3880 | Rivets total: | 12 183 |

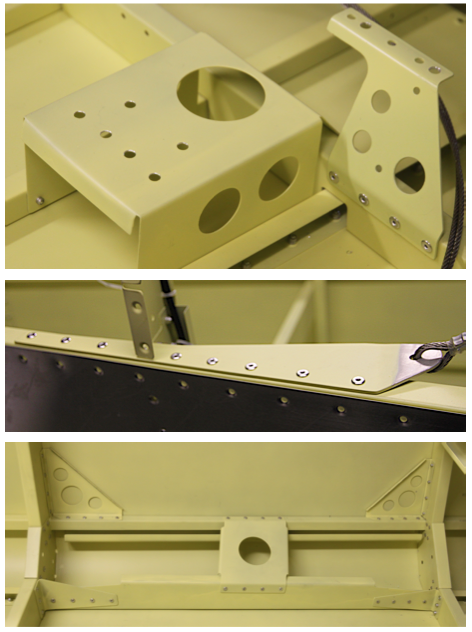

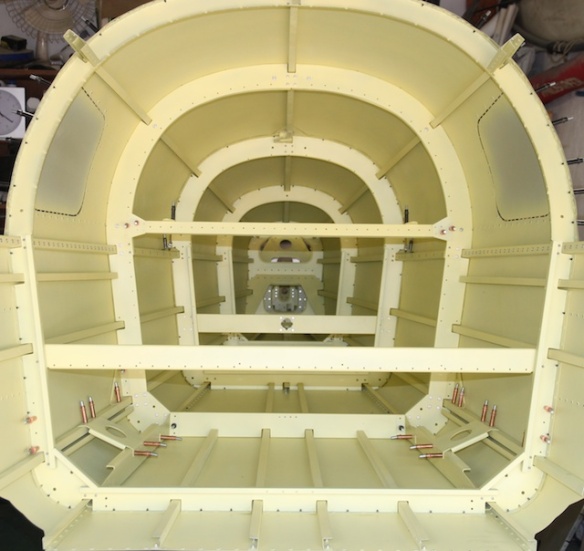

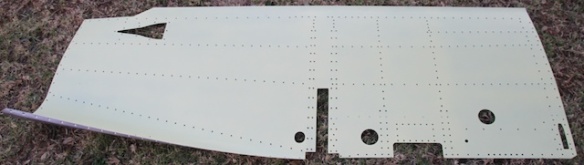

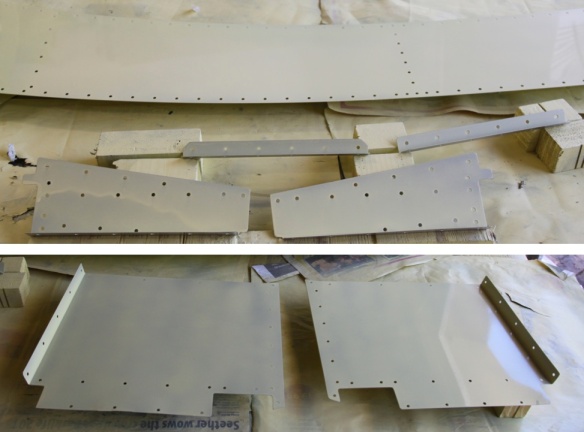

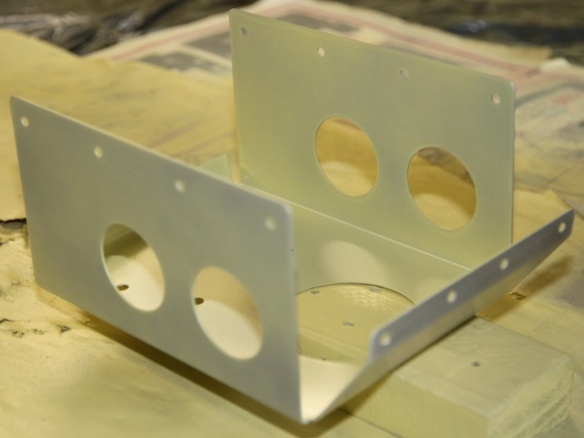

Filled all the remaining rivet heads on the rear fuselage. Add one rivet at the very rear of the plane where there was a hole that needed drilling to put in a rivet. Test fitted sides to the Centre Fuselage and floor. Realised that the sides are going to need some prep, and that I should really start by fitting the floor of the forward part of the cockpit.